ANATOMY OF A SHIPPING CONTAINER

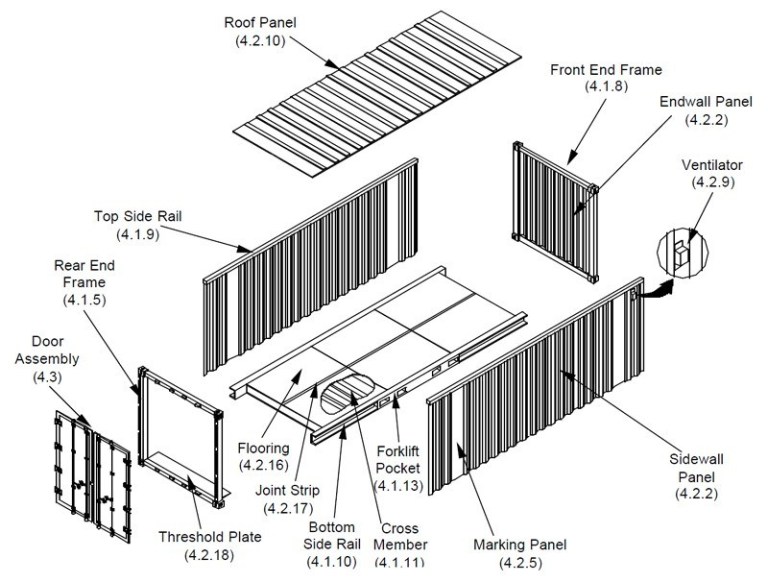

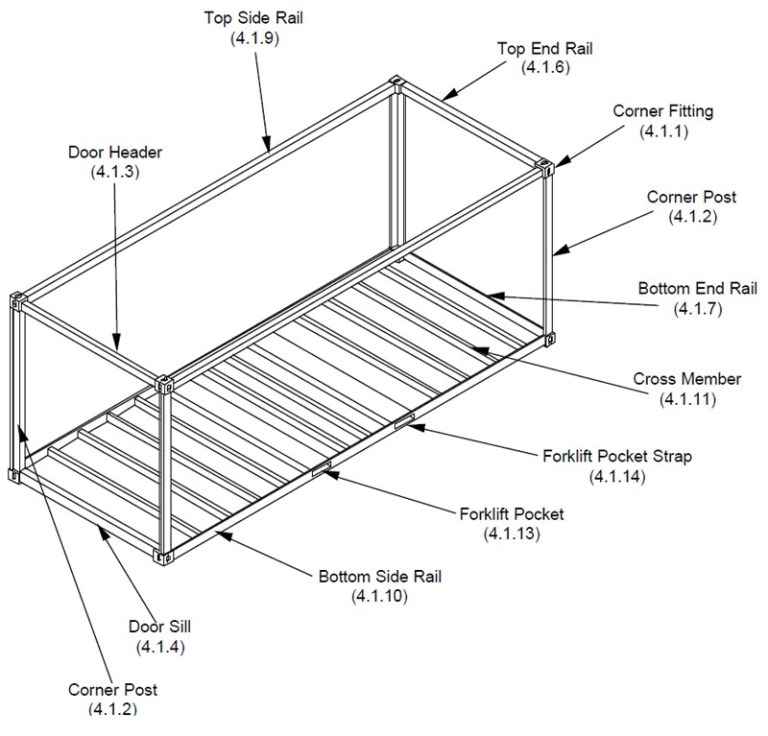

The container which comes in various sizes/types is made up of various structural components that all work together to form a rigid rectangular structure capable of handling various types of cargo.

ANATOMY OF A SHIPPING CONTAINER

The container which comes in various sizes/types is made up of various structural components that all work together to form a rigid rectangular structure capable of handling various types of cargo.

Writen by Robert Wheeler 22/02/2021

The shipping or freight container came into being in 1956 and changed global trade forever.. From then there has been no turning back for this CTU (Cargo Transport Unit).

The container which comes in various sizes/types is made up of various structural components that all work together to form a rigid rectangular structure capable of handling various types of cargo.

The main structural components are :

- Roof

- Side Walls

- Floor

- Cross Members

- Top/Bottom Rails, and

- Corner Posts

All of these components transfer weight and racking forces when a box is loaded or empty be it at sea or on a trailer at the back of a truck being transported around.

Repairs to a container which are part and parcel in the life of a container play an important role in the condition of a container.

For example, an “Improper Repair” on say 3 cross members whereby the cross members have been cut through the full profile of the cross member has actually weakened the structure of the cross member.

This ultimately leads to the weakening of the plywood floor. Remember forklift trucks move in and out of the container whilst loading which can cause sagging or cracking on a floor with an improper type of repair which could inevitably lead to having to section or replace the floorboard.

The correct way to have inserted the cross member would have been to stop the vertical cut to between 13 mm – 20 mm away from the top flange, then remove the damaged section of the cross member leaving the original piece intact and then welding the new section into place. Thus not removing the top portion of the cross member.

This is just one of many examples, there are too many to mention. I will now touch on some of the actual components:

1) The Roof: Made of Corten Steel Sheets with corrugated profiles to give the roof strength and rigidity. Weaknesses here on older units are, pitting and bubble rust which if the box is dropped too hard can lead to tiny pinholes forming around the corroded area.

Usually this can only be seen from the top exterior of the roof panel. Or when it may be turned into a depot for whatever reason. Even then it can still be missed.

2) Side Wall Panels: Made of Corten Steel Sheets with corrugated profiles for strength and rigidity. Again older units can be prone to rusting at the bottom lower half of the panel next to the top half of the bottom rail at the weld seam. This is more visible than the roof.

Weaknesses on panels are impact damages and bowing. Normal IICL5 acceptable damage criteria here is not more than 50 mm bowing into the cube on any one side if bowing is on both opposite sides than the criteria is 25 mm.

3)Floor and Cross members: The floor consists of 28 mm Laminated Marine Plywood.

Weaknesses here would be improper sections on the flooring not covering 3 cross members in other words a too short a piece of plywood flooring fitted. This can lead to sagging and cracking.

Cross members are structural components (visible from underneath the container) that make up the floor along with forklift pockets. They too can have weaknesses as described above along with bowing below the bottom face of a corner casting.

Units in this condition fall outside of the recommended IICL5 repair criteria. And should be repaired if being used for cargo transportation. Hairline finger fractures on flooring can be from Inferior material having being used or general wear and tear.

4) Top and Bottom Rails: The rails form the frame of the container. Top rails can be either box section profiles or 10mm flat bar profiles. Bottom rails should have no cracks around the corner casting at weld points where the rail meets the casting likewise top rails too.

Rails and panels should not be bowing our bowed outside the “Container Envelope” by more than 40mm. Door end and front end bottom rails have “Cuts Outs” which helps to stop the rail from being pierced from the twist-lock points when being loaded onto a trailer.

5) Corner Posts Front End and Door End: All corner posts are made up of 10mm High Tensile Steel. Strict repair criteria is enforced on repairs that must conform to IICL5 repair criteria. Unsafe repairs to corner posts could result in the collapse of a stack.

What to look for would be previous inserts that are less than 300 mm in length, inserts that terminate within 300 mm from the corner casting, and full profile inserts on the front end posts [fixed end]. Any splits our hair line cracks on previous post insert welds.

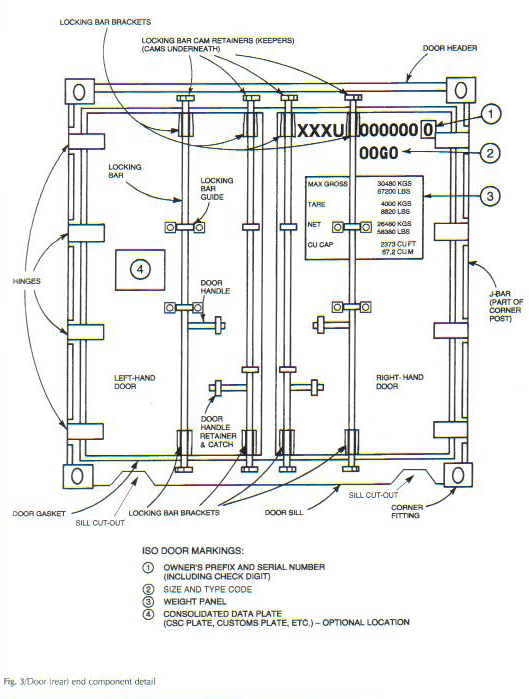

6) Doors ,Fittings and CSC Plate: Doors should open to 180 deg, hinge pins should be intact at each hinge and not missing.

Door gaskets should not be hanging or loose, and when both doors closed if need be a “Daylight Check” can be carried out ensuring no holes and box is sealing.

Each and every container must have a CSC Plate on the left hand door short for [Container Safety Convention].

This plate has all the details of the Owners, Technical Data, and ACEP information. ACEP being short for, Approved Continuous Examination Programme, in short every 30 months a container must be turned into a Container Depot for examination.

Conventions

Containers are governed by laws, regulations, conventions and standards on both an international and national basis. Many of the international conventions have been established under the umbrella of the United Nations and its sponsored organizations. National laws and regulations have been developed to apply the international conventions and national requirements.

1) Customs Convention on Containers, 1972, entered into force on the 6th of December 1975 and overseen by World Customs Organization (WCO) recognizes containers as Instruments of International Traffic (IIT) and establishes framework for containers to be used in international transportation.

2) The 1972 Convention for Safe Containers overseen by the International Maritime Organization (IMO) has two goals. One is to maintain a high level of safety of human life in the transport and handling of containers by providing generally acceptable test procedures and related strength requirements. The other is to facilitate the international transport of containers by providing uniform international safety regulations.

3) The International Standards for freight containers overseen by the International Organization for Standardization’s (ISO) have allowed “the box” to become the backbone of global supply chains. To date, over 30 International Standards exist in this domain. They cover a wide variety of aspects of different types of freight containers that include air/surface/(intermodal) containers, containers on board vessels, tank containers, platform and platform-based containers.

Source: https://www.shippingandfreightresource.com/